Slip-and-fall incidents are among the most frequent problems faced in the foodservice industry. Every year, it's estimated that over 3 million foodservice workers and 1 million customers suffer injuries due to such accidents. This alarming figure continues to rise by approximately 10% annually. What’s the primary cause of these accidents? Wet and hazardous floors.

While there are measures to prevent these incidents—such as installing appropriate flooring that's easy to clean and encouraging employees to wear slip-resistant shoes—floor troughs remain essential in commercial kitchens. They ensure proper liquid drainage. But can floor troughs be combined with gratings that reduce the risk of slips?

In this article, we'll explore IMC's anti-slip grating and how it helps minimize slip-and-fall accidents. Let’s dive in.

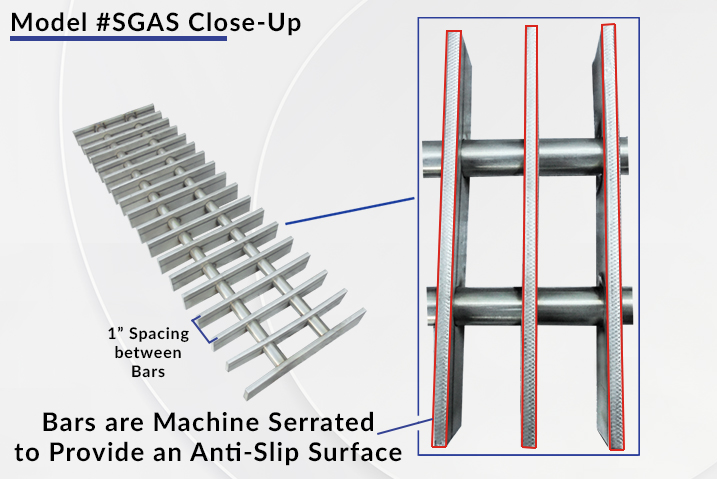

**Model #SGAS – IMC’s Top-of-the-Line Anti-Slip Grating**

IMC’s proprietary stainless steel anti-slip grating is known as **Model #SGAS**. Constructed using 1†x 3/16†Type 304 series stainless steel bars, it’s connected by (2) ½†stainless steel rods. The standard bar spacing is 1â€, though an ADA-compliant version with ½†spacing is also available.

What sets this grating apart is its surface treatment. The bars are deeply grooved through a machine serration process, creating a genuine anti-slip texture. This "rough" surface ensures that footwear maintains better grip. Here's a closer look:

**Why Choose Anti-Slip Grating?**

The decision to use anti-slip grating depends largely on your facility's needs. If your floors are consistently wet, anti-slip grating becomes almost indispensable. For instance, when combined with poor lighting or uneven surfaces, wet floors can lead to serious accidents. Rugs or mats may seem like quick fixes, but they often wear out quickly and become unsanitary, necessitating constant replacement.

With anti-slip grating, the likelihood of slip-and-fall accidents decreases significantly thanks to its deeply grooved surface. Coupled with the durability of stainless steel, this offers a long-term solution.

**Alternative Materials to Stainless Steel?**

If stainless steel isn’t feasible for your project or you’re working within a tighter budget, fiberglass alternatives are available. Specifically, IMC models **#PFG** and **#CH**.

The **PFG** is built using 1†deep “I†bars with a rough surface providing excellent traction. The **CH**, on the other hand, is crafted from a tougher polyester resin with molded squares. Its gritty surface excels at keeping footwear firmly grounded.

One of the worst scenarios in a commercial restaurant setting is a preventable slip-and-fall incident. Anti-slip grating offers the ideal solution to this persistent issue. To learn more about IMC’s grating solutions, click [here](http://www.imcgrating.com).

---

*Disclaimer: The opinions and information shared in this article represent the views of IMC/Teddy. The content is intended for educational purposes only. For any inquiries regarding featuring this article, please reach out to IMC/Teddy directly. Thank you.*

---

**Sharing Options:**

Feel free to share this article with others!

• Share on [Facebook](#)

• Share on [Twitter](#)

• Share on [LinkedIn](#)

• Share on [Pinterest](#)

---

As someone who works in or manages a foodservice business, safety should always be a top priority. By investing in high-quality anti-slip grating, you're not just protecting your staff and customers—you're also ensuring smoother operations and potentially saving costs associated with accidents. Whether you opt for stainless steel or fiberglass, the right choice can make all the difference.

ultrasound equipment,Doppler ultrasound device,Doppler ultrasound scanner

Sichuan Kairuisheng Electronic Technology Co., Ltd , https://www.sckrayson.com